SERIES

Machines that run and run

Monitoring of cleaning machines extends their lifetime and reduces costs. So let's take a look at a Cleaning Machines product that focuses exactly on this issue.

(česká verze)

Monitoring of cleaning machines extends their lifetime and reduces costs. So let's take a look at a Cleaning Machines product that focuses exactly on this issue.

(česká verze)

Our Internet of Things technology constantly monitors the operation, behavior, and location of your cleaning machines. So that you can be confident they are operating at peak efficiency, being used correctly and safely, and creating an accurate audit trail of work completed. And with a new predictive approach to maintenance you can prevent costly repairs and breakdowns in order to ensure you deliver the quality and continuity of service your customers expect.

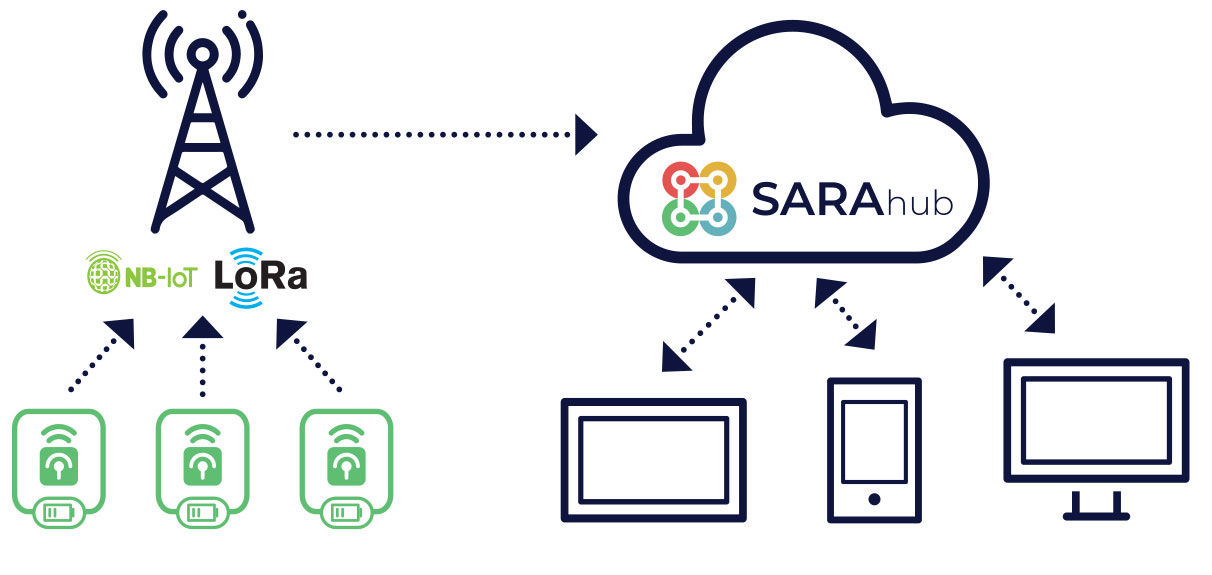

SARAhub (Smart Assets Rapid Action) is easy-to-use environment for highly responsive IoT. SARAhub acts as a central nervous system for your assets – receiving information, processing it and triggering action when necessary in response to important events. It enables you to displays sensors and devices in hierarchical dashboards, creating digital twin of your environment. It allows you to set up automated responses to specific situations, data consolidation, and many other features

Integration and responsiveness are key advantages of SARA.hub. Integration of both different systems on input and output and different agendas into one environment. There is no need to deploy various systems for environmental monitoring, equipment maintenance or readings and energy control. All is in one environment, in which it is then possible to define reactions to different situations.

An example of a sensor designed to monitor the condition and position of equipment.

SARAhub is an easy-to-use environment where deployment of Internet of Things (IoT) scenarios is much easier.

In the next article, we will briefly introduce Energy Monitoring which is becoming more and more important, especially nowadays, when we are struggling with the energy prices. Because those who measure, save.

Monitoring of cleaning machines extends their lifetime and reduces costs. So let's take a look at a Cleaning Machines product that focuses exactly on this issue.

Industrial boiler rooms, heat exchanger stations or other similar operations are characterized by the fact that they combine several specific devices from different manufacturers and therefore have greater demands on the measurement of the operating unit and the monitoring of its behaviour.

Control of the delivery of cleaning services and the possibility of operational back-up. All this is provided by our Cleaning Control solution, based on RFID chip technology.

There is certainly no dispute that work efficiency can be increased by creating a high-quality and healthy work environment. But how can IoT help us with this? You will find out in the next part of our miniseries.

If maximum security of important and sensitive data is important to you, then the last part of our series is especially for you. We will talk about non-invasive monitoring of server and data rooms using IoT elements.